Call: 08045475713

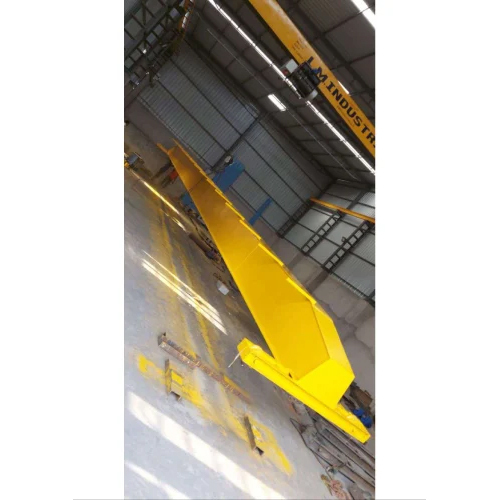

2 Ton Single Girder Crane

Price 355000 INR/ Piece

MOQ : 1 Piece

2 Ton Single Girder Crane Specification

- Working Presssure

- Standard atmospheric pressure (not applicable for electric cranes)

- Condition

- New

- Crane Total Weight

- Approx. 1800 Kg Kilograms (kg)

- Crane Traveling Speed

- 10-20 m/min (Variable as per requirements) mm/m

- Power Source

- Electric

- Trolley Travel Speed

- 15 m/min

- Feature

- Robust design, Low maintenance, Smooth operation

- Usage

- Industrial

- Crane Type

- Single Girder Crane

- Application

- Industrial Material Handling

- Span Length

- 6-20 meters (Customizable) Meter (m)

- Loading Capacity

- 2 Ton Long Ton

- Product Type

- Single Girder Crane

- Lifting Time

- 5 m/min (approx.) Minutes

- Lifting Capacity

- 2 Ton Long Ton

- Lifting Height

- 6-12 meters (depending on requirement) Meter (m)

- Control Type

- Pendant Control / Remote Control

- Emergency Stop

- Yes

- Color

- Yellow

- Material of Construction

- Mild Steel / Structural Steel

- Duty Class

- Class II / Medium Duty

- Installation

- Available on request

- Operating Environment

- Indoor / Outdoor

- Voltage Requirement

- 415 V, 3 Phase, 50 Hz

- Hoist Type

- Electric Wire Rope Hoist

- Mounting

- Top Running / Under Slung

- Optional Accessories

- Wireless Remote Control, Overload Protector, Anti-collision device

- Standards

- IS 807 & IS 3177 compliant

- Finishing

- Powder Coated / Painted

2 Ton Single Girder Crane Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About 2 Ton Single Girder Crane

We are offering 2 Ton Single Girder Cranes which are commonly used in steel and metal industries, where they are used handling & moving steel bars, pipes, plates, & many other heavy metal products. In addition, they are also used in construction sites to life and/or move construction materials, like cement bags, bricks, and steel beams.

Specifications of 2 Ton Single Girder Crane

|

Capacity |

2 ton |

|

Span |

10-20 m |

|

Hoist Travelling Speed |

5-10 m/min |

|

Brand |

L.M. |

|

Material |

Iron |

|

Surface Treatment |

Galvanized |

High-Quality Construction

Manufactured using mild steel or structural steel, the crane exhibits exceptional durability and strength. The powder-coated or painted finish enhances corrosion resistance, making it suitable for demanding industrial environments. Compliance with IS 807 & IS 3177 ensures reliability and structural safety.

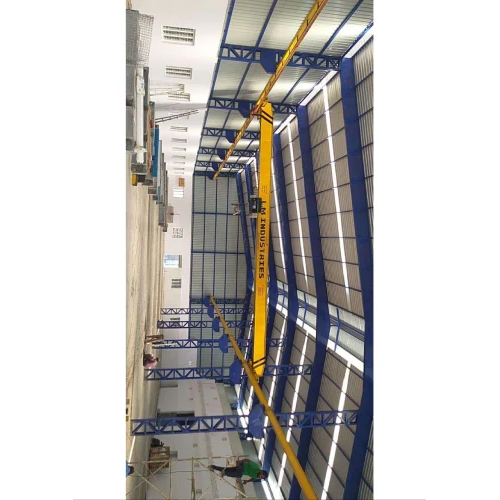

Versatile Installation and Application

This crane is customizable for top running or under slung mounting and is designed for easy installation, which can be arranged upon request. It effectively serves various industries, performing reliable material handling in both indoor and outdoor settings, thanks to its robust design and flexible operating environment.

Reliable Operation and Safety

Equipped with an electric wire rope hoist, pendant or remote control, limit switches, emergency stop, and optional accessories like overload protector and anti-collision devices, the crane assures safe, efficient, and smooth operations. Its medium duty cycle and 2-ton capacity make it suitable for consistent industrial use.

FAQs of 2 Ton Single Girder Crane:

Q: How is the 2 Ton Single Girder Crane installed at an industrial site?

A: Installation services are available on request and conducted by skilled technicians. The crane can be mounted as either top running or under slung based on site requirements, ensuring optimal alignment and safe operation for your facility.Q: What are the advantages of using an electric wire rope hoist in this crane?

A: An electric wire rope hoist provides smooth, precise lifting and lowering capabilities, reduces manual effort, and enhances operational safety. It allows consistent material handling with reduced maintenance and increased efficiency.Q: When should I opt for optional accessories like wireless remote control or anti-collision devices?

A: Optional accessories are recommended for facilities focusing on advanced safety, enhanced operator convenience, and increased automation. Wireless remote controls improve mobility, while anti-collision devices minimize risks, particularly in busy or multi-crane environments.Q: Where can this crane be utilized effectively?

A: This single girder crane is suitable for indoor and outdoor industrial environmentssuch as factories, warehouses, assembly lines, and workshopswhere reliable and efficient material handling is essential.Q: What is the process for customizing the span length and lifting height?

A: Customization is achievable during the ordering process by specifying your required span length (620 meters) and lifting height (612 meters). The manufacturer will tailor the crane to your operational needs, ensuring optimal performance.Q: How does this crane enhance material handling efficiency and safety?

A: The design features, including robust construction, smooth operation, limit switches, emergency stop, and optional safety accessories, contribute to efficient, safe lift and transfer of materials while minimizing downtime and supporting workplace safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese