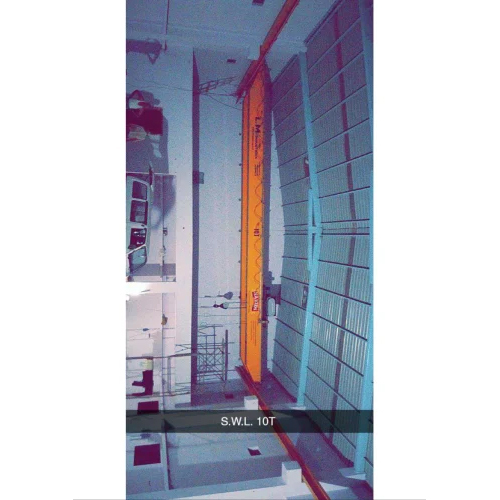

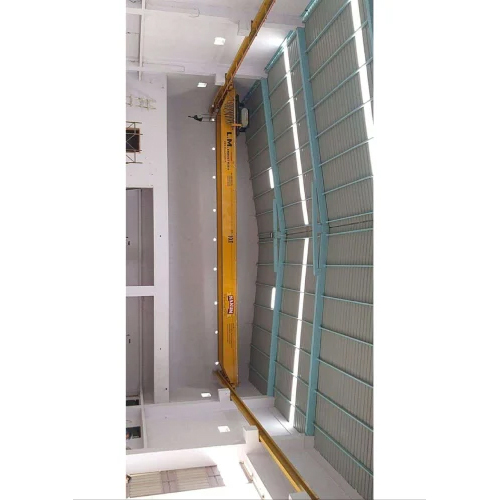

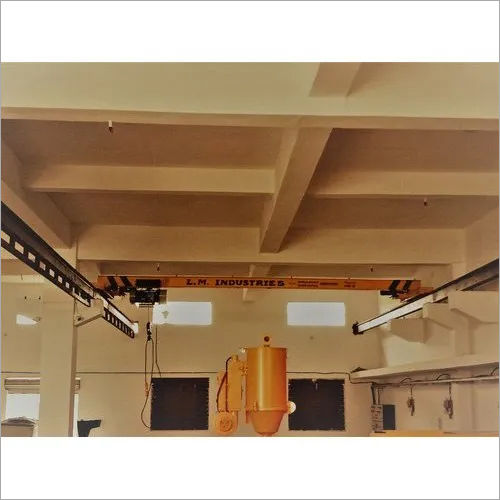

5 Ton Sew Double Girder EOT Crane

Price 360000 INR/ Piece

5 Ton Sew Double Girder EOT Crane Specification

- Feature

- Other

- Condition

- New

- Usage

- Industrial

- Material

- Mild Steel

- Size

- Standard

- Application

- Construction

- Product Type

- Double Girder EOT Crane

- Color

- Yellow

- Warranty

- 1 Year

5 Ton Sew Double Girder EOT Crane Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About 5 Ton Sew Double Girder EOT Crane

|

Span |

10-20 m |

|

Hoist Traveling Speed |

5-10 m/min |

|

Brand |

L.M. |

|

Material |

Iron |

|

Surface Treatment |

Galvanized |

|

Capacity |

5 ton |

Precision Engineering for Industrial Efficiency

This double girder EOT crane is meticulously engineered for maximum lifting efficiency in industrial and construction contexts. Its dual-girder configuration allows for better load distribution and increased operational stability. Trusted by industries across India, its a vital asset for streamlining material movement and improving overall productivity.

Proven Benefits in Construction

With a lifting capacity of 5 tons and a sturdy yellow frame, this crane excels in challenging construction environments. Its reliable mechanisms ensure worker safety while supporting the rigorous demands of modern building sites. The distinct color and design prioritize both visibility on-site and operational safety.

FAQs of 5 Ton Sew Double Girder EOT Crane:

Q: How does a Double Girder EOT Crane differ from a single girder crane in industrial use?

A: A double girder EOT crane, like this 5 Ton Sew model, uses two parallel girders for added rigidity and stability. This design enables it to lift heavier loads compared to single girder cranes, making it suitable for demanding industrial and construction tasks.Q: What are the main benefits of using a 5 Ton Sew Double Girder EOT Crane for construction projects?

A: The main advantages include higher load capacity, enhanced structural stability, increased operational safety, and efficient material handling. Its design is tailored to meet the heavy-duty requirements typical of construction and industrial environments.Q: Where can this double girder EOT crane be installed?

A: This crane is ideal for installation in industrial facilities, construction sites, warehouses, and manufacturing units where robust overhead lifting is essential. Its adaptability ensures seamless integration into various industrial settings across India.Q: When should you choose a double girder EOT crane over other types?

A: Opt for a double girder EOT crane when your project demands frequent lifting of heavy or oversized loads, especially in new construction or industrial setups. Its design provides greater headroom and spans, making it suitable for large-scale operations.Q: What is the process for installing and commissioning the 5 Ton EOT crane?

A: Installation involves site assessment, structural readiness, positioning the crane, securing the girders, and conducting safety checks. Professional commissioning ensures all systems function correctly, maximizing operational safety and performance from day one.Q: How is this crane maintained for long-lasting performance?

A: Routine inspections, timely lubrication, checking electrical systems, and periodic replacement of wear parts are crucial. Regular professional maintenance helps to ensure safety, reliability, and continuous performance in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EOT Crane Category

1 Ton Single Girder EOT Crane

Price 310000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Usage : Industrial

Material : Mild Steel

Product Type : Single Girder EOT Crane

5 Ton Single Girder EOT Crane

Price 310000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Usage : Industrial

Material : Mild Steel

Product Type : Single Girder EOT Crane

5 Ton Double Girder EOT Crane

Price 555000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Usage : Industrial

Material : Mild Steel

Product Type : Double Girder EOT Crane

Double Girder EOT Crane

Price 215000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Usage : Industrial

Material : Iron

Product Type : Double Girder EOT Crane

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese