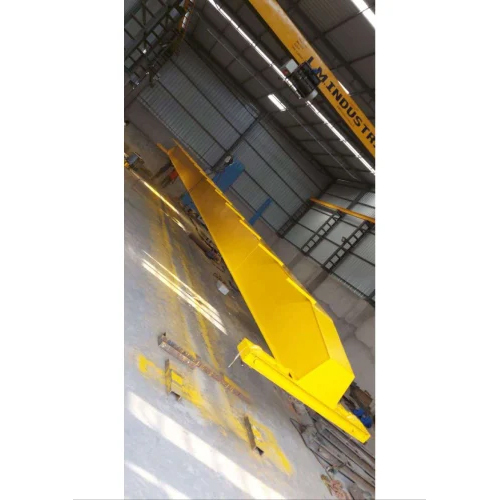

5 Ton Single Girder EOT Crane

Price 310000 INR/ Piece

5 Ton Single Girder EOT Crane Specification

- Condition

- New

- Usage

- Industrial

- Material

- Mild Steel

- Size

- Standard

- Crane Type

- Girder

- Application

- Construction

- Product Type

- Single Girder EOT Crane

- Color

- Yellow

- Warranty

- 1 Year

5 Ton Single Girder EOT Crane Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About 5 Ton Single Girder EOT Crane

|

Girder Type |

Single |

|

Span |

10-20 m |

|

Brand |

L.M. |

|

Material |

Iron |

|

Surface Treatment |

Galvanized |

|

Voltage |

415V |

Reliable Construction for Diverse Industries

This single girder EOT crane offers superior reliability and flexibility, catering to the rigorous demands of industrial and construction settings. Its sturdy build, combined with advanced safety features, guarantees optimal performance under heavy-duty usage. The bright yellow color provides high visibility inside workspaces, further improving operational safety and efficiency.

Safety First with Emergency Stop

Safety is paramount in material handling. Featuring a quick-access emergency stop, the 5 Ton Single Girder EOT Crane lets operators immediately halt operations if an unexpected situation arises. This critical safety measure helps prevent accidents, safeguard personnel, and protect valuable assets during lifting tasks.

FAQs of 5 Ton Single Girder EOT Crane:

Q: How does the emergency stop function enhance safety in the 5 Ton Single Girder EOT Crane?

A: The emergency stop feature allows operators to instantly halt crane operations in case of any emergencies or hazardous conditions, minimizing the risk of accidents and ensuring a safe working environment.Q: What primary applications is this crane suitable for in industrial and construction projects?

A: This crane is ideal for lifting, transporting, and positioning heavy materials in factories, warehouses, and construction sites, ensuring efficient workflow and robust support for varied industrial requirements.Q: When should the 5 Ton Single Girder EOT Crane be used within a construction project?

A: It should be employed whenever there is a need to move substantial loads or construction components, particularly during material handling, assembly, or storage operations, where precision and reliability are crucial.Q: Where can the 5 Ton Single Girder EOT Crane be installed for optimal performance?

A: It is best installed in industrial facilities, workshops, or construction sites where overhead lifting and movement of heavy items are regularly required, ensuring seamless integration with existing infrastructure.Q: What is the process for acquiring and installing this crane from a manufacturer or supplier in India?

A: Customers can contact certified manufacturers or suppliers in India to discuss requirements, place an order, and arrange for professional installation, ensuring compliance with safety and operational standards.Q: How is the usage of a single girder design beneficial compared to double girder cranes?

A: Single girder cranes are more cost-effective, easier to install, and offer sufficient strength for medium-weight loads like 5 tons, making them practical for most standard industrial and construction applications.Q: What are the long-term benefits of using a new condition EOT crane for material handling?

A: A new crane offers reliable performance, minimized maintenance needs, enhanced safety features, and higher efficiency, resulting in reduced operational downtime and increased longevity of lifting operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EOT Crane Category

5 Ton Sew Double Girder EOT Crane

Price 360000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Material : Mild Steel

Crane Type : Double Girder Crane

Usage : Industrial

Double Girder EOT Crane

Price 215000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Material : Mild Steel

Crane Type : Girder

Usage : Industrial

5 Ton Double Girder EOT Crane

Price 555000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Material : Mild Steel

Crane Type : Girder

Usage : Industrial

Double Girder EOT Crane

Price 215000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Material : Iron

Crane Type : Eot

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese