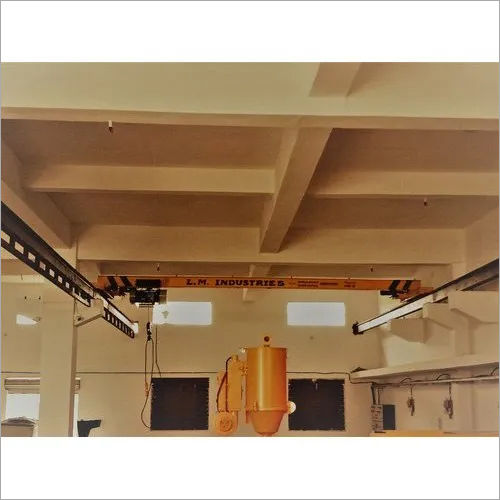

Double Girder EOT Crane

Price 215000 INR/ Piece

Double Girder EOT Crane Specification

- Usage

- Industrial

- Material

- Mild Steel

- Size

- Standard

- Crane Type

- Girder

- Application

- Construction

- Product Type

- Double Girder EOT Crane

- Color

- Yellow

- Warranty

- 1 Year

Double Girder EOT Crane Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Double Girder EOT Crane

|

Load Capacity |

1-5 ton |

|

Span |

10-20 m |

|

Hoist Travelling Speed |

5-10 m/min |

|

Brand |

L.M. |

|

Material |

Iron |

|

Surface Treatment |

Galvanized |

Robust Double Girder Design

Engineered with two strong girders, the crane offers superior stability and support during heavy lifting operations. This structure allows it to handle heavier loads compared to single girder models, making it ideal for construction sites and industrial warehouses.

Electric Powered Efficiency

The Double Girder EOT Crane operates on electricity, ensuring smooth and consistent performance. Its electric operation reduces manual effort, increases productivity, and lowers operational costs in busy industrial settings.

FAQs of Double Girder EOT Crane:

Q: How does a Double Girder EOT Crane benefit industrial construction applications?

A: A Double Girder EOT Crane provides enhanced load capacity and stability, allowing efficient handling of large and heavy materials at construction and industrial sites. Its robust design ensures safe and reliable lifting for demanding applications.Q: What is the process for installing a Double Girder EOT Crane at a construction site?

A: Installation involves mounting the crane on suitable beams, connecting the electric power supply, and calibrating control systems. Professional technicians from the manufacturer or supplier in India oversee the assembly to ensure operational safety and compliance with site requirements.Q: When should an industrial facility consider using a Double Girder EOT Crane?

A: Facilities should opt for a Double Girder EOT Crane when frequent lifting of heavy materials and precision movement are required, especially for large-scale construction projects and manufacturing operations.Q: Where are Double Girder EOT Cranes typically used?

A: These cranes are commonly found in industrial plants, construction sites, warehouses, and engineering workshops throughout India, where high-capacity lifting and material handling are essential.Q: What advantages does electric power provide for Double Girder EOT Cranes?

A: The electric power source enables seamless crane operation, minimizes manual labor, offers precise control, and promotes energy efficiency, thus improving overall productivity.Q: How is safety ensured when operating a new Double Girder EOT Crane?

A: New cranes meet stringent safety standards, including automatic overload protection and advanced control systems. Regular maintenance and training further ensure safe operation in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EOT Crane Category

5 Ton Sew Double Girder EOT Crane

Price 360000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Material : Mild Steel

Product Type : Double Girder EOT Crane

Color : Yellow

1 Ton Single Girder EOT Crane

Price 310000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Material : Mild Steel

Product Type : Single Girder EOT Crane

Color : Yellow

5 Ton Single Girder EOT Crane

Price 310000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Material : Mild Steel

Product Type : Single Girder EOT Crane

Color : Yellow

5 Ton Double Girder EOT Crane

Price 555000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Material : Mild Steel

Product Type : Double Girder EOT Crane

Color : Yellow

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese